Low Delta-T Syndrome in chilled water systems

Delta-T or ΔT in centralised air conditioning systems refers to the numerical difference between chilled water supply and chilled water return temperatures. If actual delta T at the site is less than design delta T of the chillers, this condition is called low delta-T syndrome. Low delta T syndrome can be detrimental to overall energy efficiency of the chiller plant as well as equipment life.

Cause

Low Delta T syndrome is typically caused by lowering of return chilled water temperature due to inefficient transfer of heat.

Effect

Low ΔT can lead to improper sequencing of chillers (operating more chillers than necessary) and pumps, and consequently increased energy expenditures.

Typical triggers of low delta T syndrome

1. Oversized equipment

If coils and vales are not sized properly, appropriate transfer of heat will not take place, resulting in lower return chilled water temperatures.

2. Scaling and fouling of coils due to improper maintenance

If maintenance is not carried out properly, heat transfer surfaces can get damaged which in turn affects the exchange of heat.

3. Improper balancing

Incorrect hydronic balancing can result in wasted pumping efforts during partial load conditions. This can cause lower return temperatures.

4. Increased pumping of water

Improper flow values can also lead to low delta t syndrome.

Explanation for the effect

The quantitative relationship between heat transfer and temperature change is governed by the formula:

Q= mc ΔT

Where:

Q= Chiller load in kW

m= Mass flow rate of chilled water in kg/s

C or Cp= Specific heat capacity of water= 4.186 kJ/kgK

ΔT= Temperature difference between chilled water supply and return

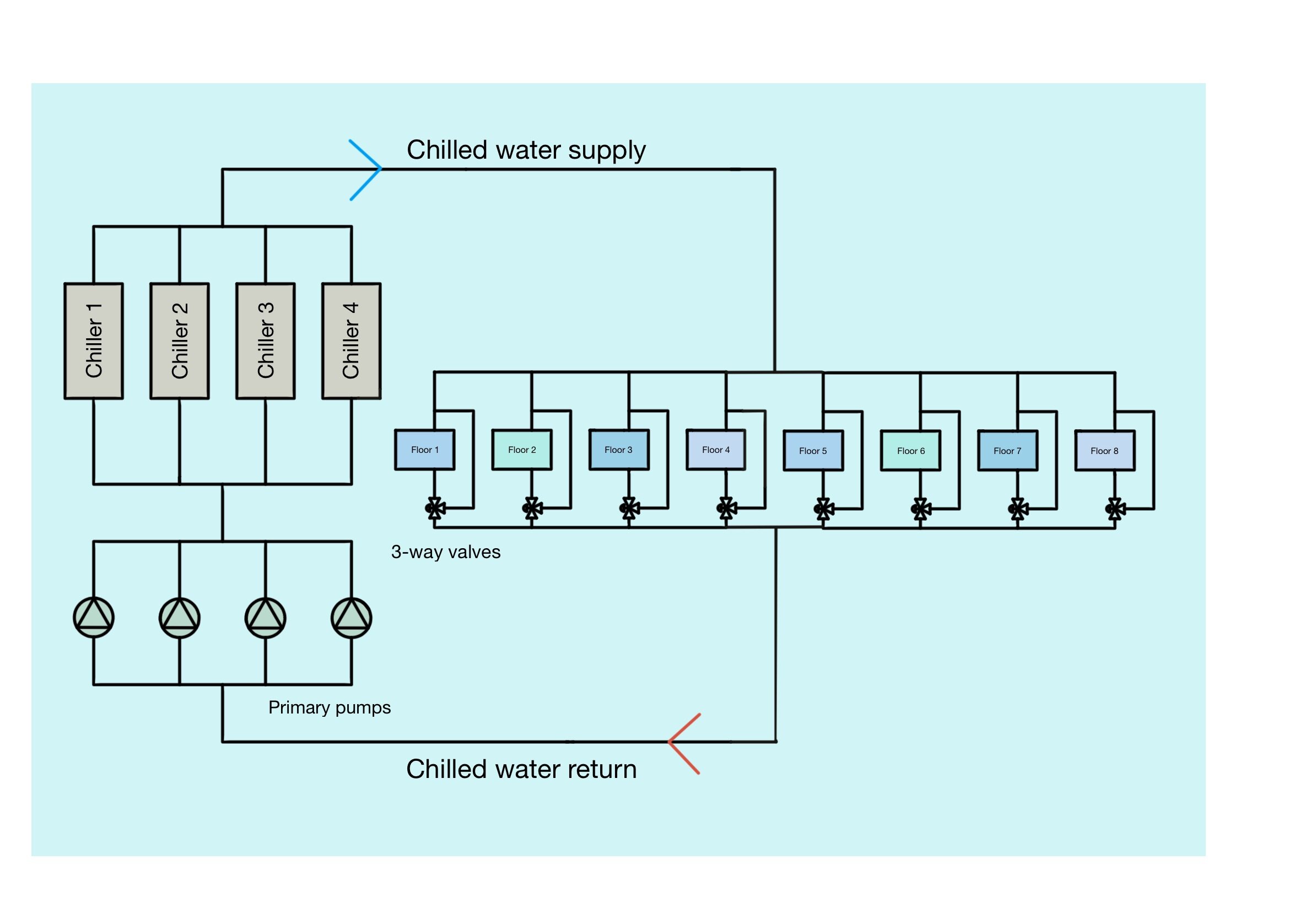

Consider the example of a theoretical building chilled water system of the following type:

Total Design Load= 1000 TR

No. of chillers= 4 (250 TR each)

CHWS= 6°C (Chilled water supply temperature)

CHWR= 12°C (Chilled water return temperature)

Design ΔT= 12-6=6

The building has 8 floors, each with a cooling requirement of 125 TR.

Flow rate calculation:

M=Q/ (Cp* ΔT)

;M= Mass flow rate of chilled water

;Q= Heat load or in this case, total chiller plant capacity=1000TR=1000*3.517kW=3517kW.

;Cp=4.186

; ΔT=6

Thus,

M=(1000*3.517)/ (4.186*6)

=140 kg/s

Convert mass flow rate to volume flow rate:

VFR=MFR/Density

=140/998.2

=.14 m3/s=.14*60 m3/min=8.4 m3/min = 8.4*264 GPM=2217.6 ~ 2218 GPM.

Therefore, chilled water flow rate required = 2218 GPM.

Flow rate for each floor= 2218/8=277.25 GPM

Consider 2 cases:

1. Operation at full load

At full load condition, 6°C water that enters the terminal equipment (AHU, FCU, etc.) or ‘load’ will absorb heat from the load and increase its temperature to 12°C. Therefore all 277.25 GPM of chilled water supply will flow through the coil without bypassing across the 3-way valve. In this case, delta T across chiller will be 6.

2. Operation at partial load

At partial load, when the requirement drops to half, the 3-way valves allow bypass of the chilled water and thereby limit flow through cooling coil. This bypass lets 6°C water mix directly with 12°C return line. Consider 50% of chilled water supply is bypassed at 50% load (This figure is taken for simplicity of calculation. In actual practice more than 50% of chilled water is bypassed for meeting a 50% partial load.). In this case, around 138.625 GPM of water is bypassed.

Thus, temperature of return chilled water line reduces to

(138.625*6+138.625*12)/277.25=9

Actual ΔT=9-6= 3

This new ΔT of 3 has an important implication as it has now changed the loaded capacity of the chillers.

Chiller loading= ΔTA/ ΔTD

; ΔTA= Actual Delta T

; ΔTD= Design Delta T

Chiller Loading= 9/12= 0.75

The typical chiller which has a tonnage rating of 250 TR now has a usable capacity of only 75% of its original rating which is (.75*250) 187.5 TR.

If 4 out of 8 floors are vacant with 0 load, the total cooling requirement reduces to 500 TR. This requirement of 500 TR can be met with 2 chillers ideally (250*2), but due to low delta T syndrome, chiller capacities are reduced and hence 3 chillers need to be operated to meet the load. This results in increased energy usage and consequently greater operational costs.